Collection: Aluminum Coil

Professional-grade Aluminum Coil for Seamless Gutter fabrication and custom trim applications. From economical .027" gauge to premium .032" gauge Gutter materials, plus versatile Trim Coil for finishing work - everything contractors need for complete aluminum fabrication projects.

-

.032" Aluminum Gutter Coil (15" Width)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

.027" Aluminum Gutter Coil (11-¾" Width)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

.032" Aluminum Gutter Coil (11-¾" Width)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

Aluminum Trim Coil (24-Inch x 50' Roll)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per

How to Choose the Right Aluminum Coil

Material selection depends on your specific application and performance requirements.

Gutter Coil thickness determines both cost and durability - .027" gauge offers cost savings for budget-conscious installations, while .032" gauge provides industry-standard strength for demanding applications. Trim Coil serves different purposes entirely, designed for wrapping fascia boards, custom flashing, and architectural details rather than water management.

Consider your project scope when selecting materials:

- Budget installations - .027" Gutter Coil delivers seamless benefits at reduced cost

- Standard residential and commercial installs - .032" Gutter Coil provides optimal durability and workability

- Custom trim work - Trim Coil handles fascia wrapping, flashing, and decorative applications

- Color requirements - .032" gauge and Trim Coil offer complete color selection; .027" gauge limited to white

Preparing Your Seamless Gutter Installation

Successful Seamless Gutter fabrication begins with proper equipment setup and material handling. Gutter Machine calibration ensures consistent forming throughout the job - verify roller alignment, adjust for material thickness, and test-form sample sections before beginning production runs. Coil positioning affects both efficiency and quality - secure coils properly on truck-mounted equipment and maintain consistent feed tension to prevent material buckling or stretching.

Pre-installation planning maximizes material utilization and minimizes waste. Job site preparation includes measuring all roof sections, identifying obstacles, and determining optimal Gutter run lengths to reduce joints. Material staging involves organizing coils by color and gauge, protecting painted surfaces from scratches, and ensuring easy access for continuous production without interruption.

Conversion Rates & Order Planning

Accurate material estimation prevents costly shortages and reduces waste on gutter installations. Understanding feet-per-pound conversion rates enables precise ordering and job costing for different gauge options.

Gutter Coil Conversion Rates

- .027" Gauge (11¾" width): 2.6 feet per pound - Maximum linear footage yield for economical projects

- .032" Gauge (11¾" width): 2.24 feet per pound - Standard conversion for 5-Inch gutter fabrication

- .032" Gauge (15" width): 1.75 feet per pound - Heavy-duty option for 6-Inch gutter systems

Planning Guidelines

- Add 10% waste factor for cuts, overlaps, and fabrication adjustments

- Account for color breaks when ordering multiple sections requiring different finishes

- Consider coil weight limits for truck-mounted equipment when sizing orders

- Plan 24-hour minimum lead time for all custom coil specifications

Product Comparison

| Product | Gauge/Thickness | Width Options | Color Selection | Primary Application |

|---|---|---|---|---|

| .027" Gauge Gutter Coil | .027" gauge aluminum | 11¾" only | White, 80 Degree White | Economical 5-Inch Seamless Gutters |

| .032" Gauge Gutter Coil | .032" gauge aluminum | 11¾" | All available colors | Premium 5-Inch Seamless Gutters |

| .032" Gauge Gutter Coil (15") | .032" gauge aluminum | 15" | All available colors | Premium 6-Inch Seamless Gutters |

| Aluminum Trim Coil | .019" gauge aluminum | 6" to 24" widths | 20+ colors with white reverse | Fascia wrapping, flashing, trim work |

You'll Also Need...

-

.032" Aluminum Gutter Coil (11-¾" Width)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

.032" Aluminum Gutter Coil (15" Width)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

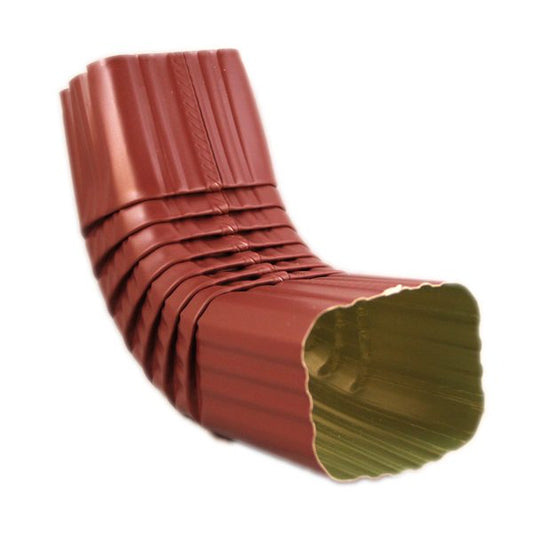

2×3" A-Style Elbow

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

2×3" B-Style Elbow

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

2×3" Downspout

Regular price $0.00Sale price $0.00 Regular priceUnit price / per

Frequently Asked Questions

This is a general guide only and may not address your specific site conditions. If you are not experienced with this type of work, hire a qualified contractor.

What's the main difference between .027" and .032" gauge Aluminum Coil for Gutters?

.032" gauge is thicker and more durable, providing better dent resistance and longevity. .027" gauge offers significant cost savings and works well for budget-conscious installations, but requires more careful handling. The thicker .032" gauge is considered industry standard for most residential applications.

Can I use the same Gutter Machine for both .027" and .032" gauge coils?

Yes, standard Gutter Machines work with both gauges, though you may need slight adjustments for the thinner .027" material. The key is maintaining proper feed tension and ensuring rollers are aligned correctly for consistent forming without material damage.

How do I calculate material needs when Aluminum Coil is sold by the pound?

Use our conversion rates: .027 gauge yields 2.6 feet per pound, .032 gauge (11¾") yields 2.24 feet per pound, and .032 gauge (15") yields 1.75 feet per pound. Measure your total linear footage, add 10% for waste, then divide by the appropriate conversion rate.

What width Aluminum Coil do I need for 5-Inch versus 6-Inch Gutters?

5-Inch Gutters require 11¾" width coil, while 6-Inch Gutters need 15" width coil. The extra width accommodates the larger Gutter profile and provides adequate material for proper forming and seaming during fabrication.

Is Trim Coil the same material as Gutter Coil?

No, Trim Coil is thinner (.019" gauge) and designed for different applications. Trim Coil is perfect for wrapping fascia boards and custom flashing but isn't suitable for Gutter fabrication. Gutter Coil is thicker and engineered specifically for water management applications.

What colors are available in each type of Aluminum Coil?

.032" gauge Gutter Coil and Trim Coil are available in all our standard colors. .027" gauge Gutter Coil is only available in 80 Degree White to keep costs economical. Trim coil features colored front surface with bright white reverse for versatile installation options.

How much notice do you need for custom coil orders?

All Aluminum Coil orders require 24-hour minimum notice. This allows us to prepare your specific gauge, width, and color requirements while maintaining quality standards. Plan ahead for best service, especially during peak construction seasons.

Can Aluminum Coil be stored outdoors?

While Aluminum Coil can withstand weather exposure, store it in a dry location when possible to prevent water spots on painted surfaces. Protect coils from scratches during storage and transport, as the baked-on enamel finish provides the long-term durability and appearance.

What tools do I need for working with Aluminum Coil?

Basic tools include tin snips or brake shears for cutting, forming brakes for bending Trim Coil, and Gutter Machines for Seamless Gutter fabrication. Support both sides when cutting to prevent material damage, and use clean tools to avoid scratching painted surfaces.

Do you break down large mill coils into smaller sizes?

Yes, we routinely break down standard 300-pound mill coils into manageable 100-pound sections for easier handling and transportation. This service makes Aluminum Coil more practical for truck-mounted Gutter Machines and reduces job site handling challenges.

More About Our Aluminum Coil

American-Sourced Aluminum for Reliable Supply Chain Management

Professional contractors face increasing uncertainty in material pricing and availability due to international trade fluctuations and tariff policies. Our commitment to 100% U.S. sourced Aluminum Coil eliminates these supply chain risks while supporting domestic manufacturing capabilities. This strategic sourcing approach ensures consistent pricing, reliable delivery schedules, and quality standards that meet the demanding requirements of Professional Gutter Fabrication and Trim applications.

Domestic aluminum sourcing provides contractors with predictable cost structures essential for competitive bidding and project profitability. International tariff uncertainties can create sudden price volatility that disrupts project budgets and customer relationships. By maintaining exclusive relationships with American aluminum producers, we provide pricing stability that enables contractors to bid projects with confidence and maintain consistent profit margins throughout varying economic conditions.

Quality Assurance Through Domestic Manufacturing Standards

Our American aluminum production suppliers maintain rigorous quality control standards that ensure consistent material properties throughout every coil. Domestic manufacturing oversight provides traceability and accountability that international sourcing cannot match, particularly for critical applications requiring precise forming characteristics and long-term durability. Our U.S. sourced aluminum meets or exceeds all industry specifications while supporting the American workforce and manufacturing infrastructure.

The baked-on enamel finishing process performed at domestic facilities ensures color consistency and adhesion quality that withstands decades of weather exposure. This manufacturing control allows us to guarantee finish performance while maintaining the flexibility to accommodate custom color matching requirements for specific architectural applications.

Professional Service and Contractor Support

Contractor-focused service includes direct truck loading capabilities and flexible packaging options designed for efficient job site operations. Breaking down large mill coils into manageable sections reduces handling challenges while maintaining material quality standards. 24-hour order processing ensures pick-up reliability for you and our production team.

Submit an RFQ or Questions

Please feel free to contact us - we promise to respond to your inquiry within the next business day. For longer requests, visit our RFQ page.