Collection: Screws, Nails & Rivets

Professional-grade fasteners engineered for reliable Gutter System connections. From Hex Screws to precision Pop Rivets and premium Trim Nails, our complete fastening solutions ensure long-term performance and professional appearance.

-

-

Stainless Steel Trim Nails (1-LB Box)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

-

#10 × 1½" 410 Stainless Steel Hex Screw (50-Pack)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

#8 × ½" 410 Stainless Steel Hex Screw (100-Pack)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

#10 Rezist® Hex Screw 1½" (50-Pack)

Regular price $0.00Sale price $0.00 Regular priceUnit price / per -

How to Choose the Right Screws, Nails & Rivets

The Right Fasteners for the Job

Selecting the proper fasteners depends on your specific application and performance requirements. Load-bearing connections like hanging Gutters and securing heavy-duty Hangers require #10 Hex Screws with 1½" length for maximum holding power. Non-load-bearing applications including Elbow attachments, Downspout seams, and component connections work best with #8 Hex Screws or Pop Rivets for clean appearance.

Consider your environmental conditions when choosing materials:

- Standard outdoor applications - Rezist® Coated Screws provide 1,000-hour red-rust protection

- Coastal or high-moisture environments - 410 stainless steel offers maximum corrosion resistance

- Permanent connections - Pop Rivets create low-profile, tamper-resistant fastening

- Removable connections - Hex Screws allow future service access when needed

Connecting Your Gutter System

Fasteners are the critical connection points that hold your entire Gutter System together. Hex Screws form the structural backbone, securing Gutters to Hangers and mounting heavy-duty brackets to fascia boards. Pop Rivets provide permanent, low-profile connections for accessories, Elbows, and decorative elements where appearance matters. Trim Nails complete the installation by securing Soffit, Fascia, and exterior Trim with corrosion-resistant precision.

The key to system reliability lies in matching fastener specifications to application demands. Structural connections require the strength of #10 Hex Screws, while finish work benefits from the clean appearance of Pop Rivets and Trim Nails. Premium materials like 410 stainless steel ensure your investment performs reliably for decades, even in challenging coastal environments.

Essential Components Checklist

For Standard Gutter Installation

- #10 Rezist® Hex Screws (50-pack) - Hanging Gutters and structural connections

- #8 Rezist® Hex Screws (100-pack) - Elbow attachments and component connections

- #42 Pop Rivets (100-pack) - End Caps and decorative connections

- Stainless Steel Trim Nails (1-pound box) - Soffit and fascia installation

For Premium/Coastal Installations:

- #10 × 1½" 410 Stainless Steel Hex Screws (50-pack) - Maximum corrosion resistance for structural connections

- #8 × ½" 410 Stainless Steel Hex Screws (100-pack) - Premium non-load-bearing connections

- #42 Pop Rivets in matching colors - Permanent decorative connections

- Stainless Steel Trim Nails in matching colors - Complete system coordination

For Heavy-Duty Applications:

- #44 Pop Rivets (100-pack) - Thick materials and multi-layer connections requiring extended grip range

Product Comparison

| Product | Material | Size/Specs | Application | Key Benefit |

|---|---|---|---|---|

| #8 Rezist® Hex Screw | Steel w/ Rezist® coating | ½" length, 100-pack | Non-load-bearing connections | 1,000-hour rust protection |

| #10 Rezist® Hex Screw | Steel w/ Rezist® coating | 1½" length, 50-pack | Load-bearing structural | Superior holding power |

| #8 410 Stainless Hex Screw | 410 Stainless Steel | ½" length, 100-pack | Premium non-load-bearing | Maximum corrosion resistance |

| #10 410 Stainless Hex Screw | 410 Stainless Steel | 1½" length, 50-pack | Premium load-bearing | Ultimate strength & corrosion protection |

| #42 Pop Rivet | 100% Aluminum | 1/8" dia., 1/16"-1/8" grip | Standard permanent connections | Low-profile appearance |

| #44 Pop Rivet | 100% Aluminum | 1/8" dia., 3/16"-1/4" grip | Heavy-duty thick materials | Extended grip range |

| Stainless Steel Trim Nails | T-304 Stainless Steel | 1¼" length, 1-pound box | Exterior trim installation | No rust staining |

You'll Also Need...

-

Product title

Regular price $19.99Sale price $19.99 Regular priceUnit price / per -

Product title

Regular price $19.99Sale price $19.99 Regular priceUnit price / per -

Product title

Regular price $19.99Sale price $19.99 Regular priceUnit price / per -

Product title

Regular price $19.99Sale price $19.99 Regular priceUnit price / per -

Product title

Regular price $19.99Sale price $19.99 Regular priceUnit price / per

Frequently Asked Questions

This is a general guide only and may not address your specific site conditions. If you are not experienced with this type of work, hire a qualified contractor.

How do I choose between #8 and #10 Hex Screws for my installation?

Use #8 Hex Screws for non-load-bearing connections like attaching Elbows to Gutters, Downspout seams, and component connections. Choose #10 Hex Screws for load-bearing applications including hanging Gutters from Fascia, securing heavy-duty Hangers, and any structural connection where holding power is critical.

When should I upgrade to 410 stainless steel fasteners?

410 stainless steel provides maximum corrosion resistance and is recommended for coastal environments, high-moisture areas, or premium installations where long-term appearance matters. While they cost more initially, stainless steel fasteners eliminate rust staining and provide decades of reliable performance.

What's the difference between #42 and #44 Pop Rivets?

#42 Pop Rivets have a 1/16" to 1/8" grip range for standard materials and typical connections. #44 Pop Rivets offer 3/16" to 1/4" grip range for thicker materials, multi-layer connections, and applications requiring deeper penetration through heavy-duty components.

Can I mix different fastener types in the same installation?

Yes, using the right fastener for each application optimizes performance. Use #10 Hex Screws for structural connections, #8 Hex Screws for component attachments, Pop Rivets for permanent decorative connections, and Trim Nails for Soffit and Fascia work.

How many fasteners do I need for a typical residential installation?

For a standard 150 linear foot residential installation: 1 box of #10 Hex Screws (structural), 2 boxes of #8 Hex Screws (components), 1 box of #42 Pop Rivets (accessories), and 2-3 lbs of Trim Nails (Soffit/Fascia). Adjust quantities based on your specific project requirements.

What tools do I need for installing these different fasteners?

Hex Screws require a magnetic nut-setter or hex driver with cordless drill. Pop Rivets need a standard rivet gun and 1/8" drill bit for pilot holes. Trim Nails can be hand-driven with a hammer or installed with appropriate nail guns, depending on head size and application.

Are color-matched fasteners worth the extra cost?

Color-matched fasteners provide superior finished appearance, especially for visible connections and premium installations. While they cost slightly more, they eliminate the need for touch-up painting and provide professional results that enhance property value.

How do environmental conditions affect fastener selection?

Coastal areas, high-moisture environments, and installations with treated lumber benefit from stainless steel options. Standard Rezist® coating handles most outdoor conditions well, but stainless steel provides ultimate protection where corrosion resistance is critical for long-term performance.

Can these fasteners be used with other manufacturers' Gutter components?

Our fasteners are designed to professional standards and work with most quality gutter components. However, verify compatibility with your specific components, especially for critical load-bearing connections where proper fit and holding power are essential.

What's the shelf life of these fasteners?

Properly stored fasteners have indefinite shelf life. Keep them in dry conditions to maintain coating integrity on Rezist® products. Stainless steel and aluminum products are virtually immune to storage conditions, making them excellent for long-term inventory.

More About Our Screws, Nails & Rivets

Professional Fastener Selection for Gutter Systems

Professional Gutter installations demand reliable fastening solutions that provide long-term performance and structural integrity. Our comprehensive Screws, Nails & Rivets collection offers everything needed to secure complete Gutter Systems with confidence, from structural connections to decorative finishing touches.

The foundation of any quality Gutter installation lies in proper fastener selection. Load-bearing connections require the superior holding power of #10 Hex Screws, engineered to support the weight of water-filled Gutters and withstand wind loads. These structural fasteners feature oversized washers and true-size shanks that meet ANSI/ASME standards, ensuring reliable performance in critical applications. The 1½" length provides deep penetration into fascia boards, while magnetic self-piercing design eliminates pre-drilling for efficient installation.

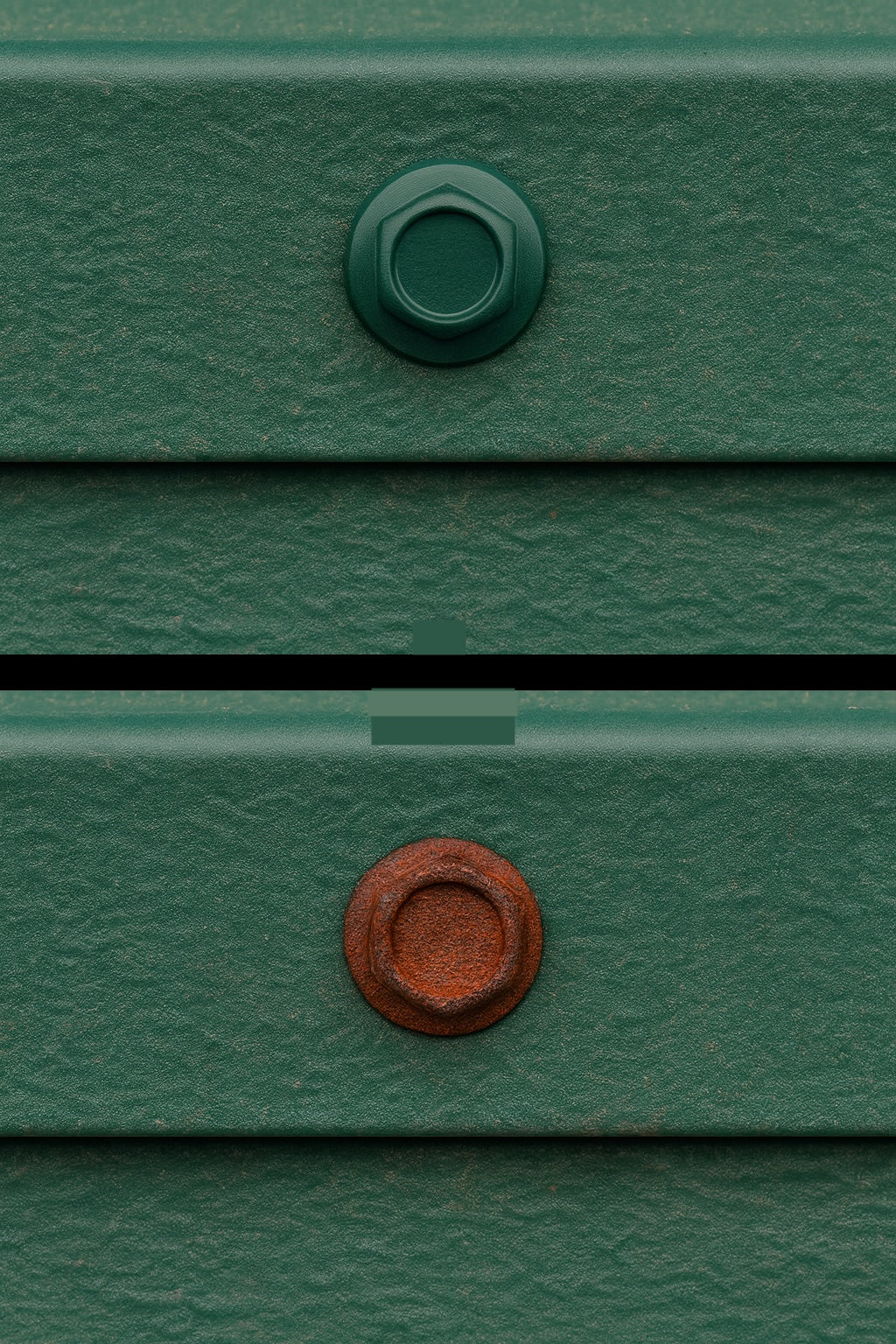

Advanced Corrosion Protection Technologies

Corrosion resistance represents a critical factor in fastener longevity and system appearance. Rezist® coated Screws provide 1,000-hour red-rust protection, dramatically outperforming standard zinc-plated fasteners that may fail in 24-48 hours. This proprietary coating system undergoes rigorous ASTM B117 salt-spray testing to verify performance claims, giving contractors and homeowners confidence in long-term reliability.

For ultimate corrosion protection, 410 stainless steel fasteners offer virtually unlimited resistance to rust and staining. The magnetic properties of 410 stainless steel, derived from its carbon content, allow efficient installation with standard magnetic tools while providing superior strength through heat-treatment capability. These premium fasteners excel in coastal environments, high-moisture applications, and installations where appearance matters most.

Specialized Fastening Solutions for Every Application

Non-load-bearing connections benefit from the precision of #8 Hex Screws, perfect for attaching Elbows, securing Downspout connections, and assembling system components. These versatile fasteners offer the same professional features as their larger counterparts, including magnetic compatibility and self-piercing tips, but in a size optimized for component connections rather than structural support.

Pop Rivets provide permanent fastening solutions where removable connections aren't needed and clean appearance is paramount. The low-profile heads create professional finished surfaces without protruding fastener hardware. #42 Pop Rivets handle standard connections with their 1/16" to 1/8" grip range, while #44 Pop Rivets accommodate thicker materials and multi-layer assemblies with extended 3/16" to 1/4" grip capability.

Premium Trim and Finishing Hardware

Trim Nails complete professional installations by securing Soffit, Fascia, and exterior Trim components. Their T-304 stainless steel construction prevents the rust staining that can occur with standard steel nails, particularly important when working with treated lumber, cedar, or redwood materials. The small 11/64" smooth heads provide inconspicuous attachment points while premium baked enamel paint ensures color coordination with complete gutter systems.

System integration considerations affect fastener selection as much as individual component requirements. Matching fastener materials to environmental conditions ensures uniform performance across all connection points. Coastal installations benefit from complete stainless steel fastening systems, while standard residential applications achieve excellent results with Rezist®-coated options.

Professional Installation and Long-Term Value

Professional contractors understand that fastener quality directly impacts callback frequency and customer satisfaction. Premium fasteners cost slightly more initially but provide significant value through reduced maintenance, improved appearance, and extended service life. The difference between quality fasteners and generic hardware becomes apparent over time, as premium options maintain their performance and appearance while lesser products may fail prematurely.

Installation efficiency improves dramatically with properly specified fasteners designed for gutter applications. Magnetic compatibility, self-piercing design, and optimized dimensions reduce installation time while improving connection quality. These professional features transform fastening from a tedious necessity into an efficient process that contributes to overall project profitability and quality.

Submit an RFQ or Questions

Please feel free to contact us - we promise to respond to your inquiry within the next business day. For longer requests, visit our RFQ page.