#8 × ½" 410 Stainless Steel Hex Screw (100-Pack)

#8 × ½" 410 Stainless Steel Hex Screw (100-Pack)

Couldn't load pickup availability

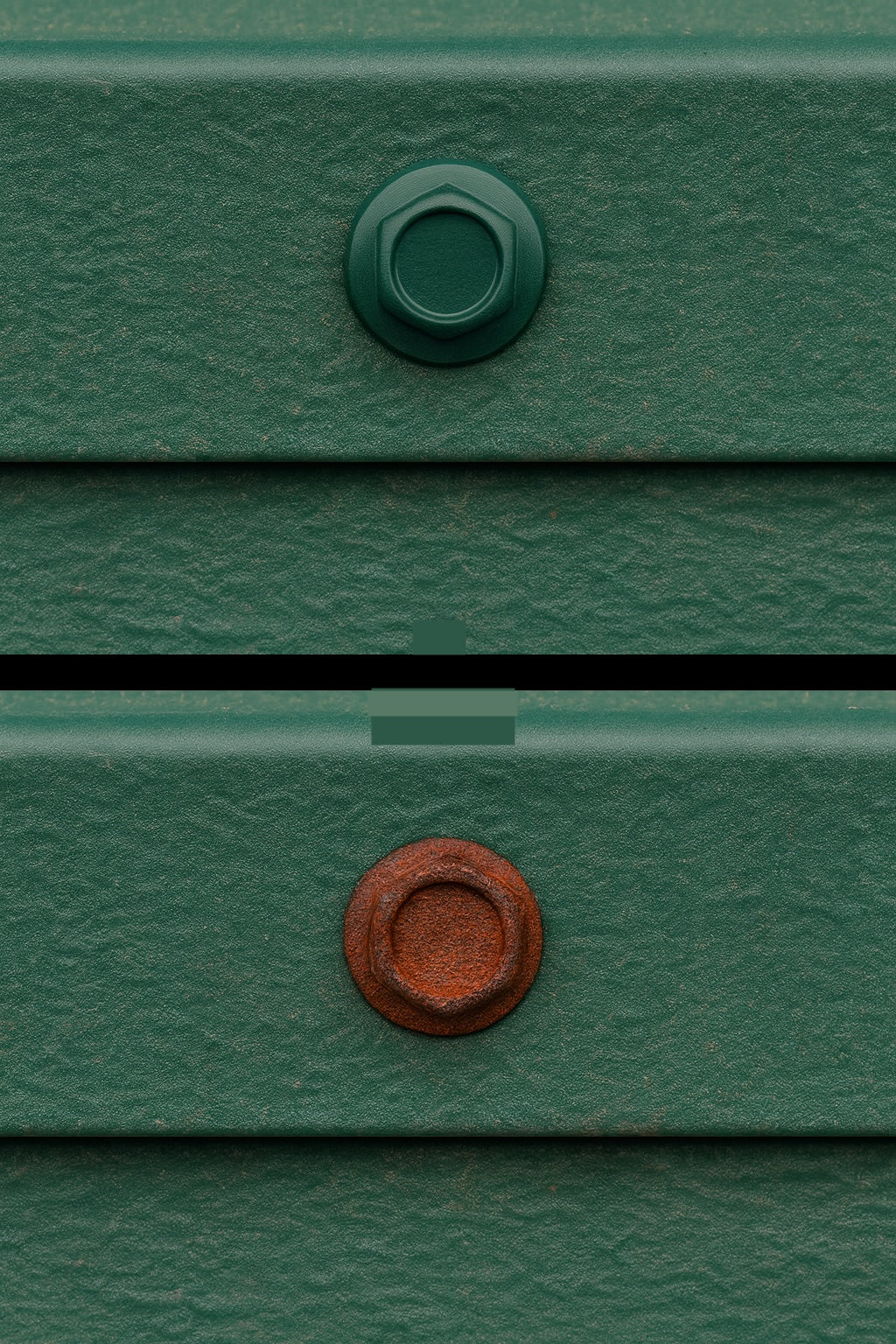

Protect your Gutter System connections with premium #8 × ½" 410 Stainless Steel Hex Screws designed for maximum corrosion resistance. These professional-grade fasteners feature magnetic 410 stainless steel construction that virtually eliminates rust staining while maintaining superior penetration strength. Perfect for coastal environments or high-moisture applications, these self-piercing Hex Screws provide the ultimate protection against corrosion while delivering efficient installation performance.

#8 × ½" 410 Stainless Steel Hex Screw (100-Pack) Key Features

-

410 stainless steel construction

Premium magnetic alloy with carbon content that forms protective oxidation film, virtually eliminating rust staining and corrosion

-

Heat-treated strength

Carbon content allows heat treatment for superior mechanical strength and penetration into Aluminum or Steel Gutter Hangers

-

Magnetic self-piercing design

Self-piercing tip eliminates pre-drilling while magnetic properties work with nut-setters for efficient overhead installations

-

Tall hex washer head

Un-slotted ¼" hex head drives faster, reduces cordless tool wear, and prevents paint build-up in threaded connections

-

Oversized washer construction

Enhanced bearing area increases pull-out resistance and provides superior clamping force for secure component connections

-

True-size dimensional accuracy

Genuine #8 shank diameter meets ANSI/ASME standards, not undersized like generic fasteners that compromise holding power

-

ASTM B117 salt-spray tested

Verified corrosion resistance through professional testing standards ensures reliable long-term performance in harsh environments

-

Premium installation efficiency

Mill finish surface, magnetic compatibility, and self-piercing design combine for faster installation with professional results

#8 × ½" 410 Stainless Steel Hex Screw (100-Pack) Material & Specifications

Material: 410 Stainless Steel (magnetic, heat-treatable alloy)

Size: #8 × ½"

Head Type: ¼" Un-slotted hex washer head

Design: Self-piercing magnetic tip with oversized washer

Finish: Mill finish

Testing: ASTM B117 salt-spray tested

Packaging: 100 pieces per pack

Use: Premium non-load-bearing Gutter System connections requiring maximum corrosion resistance

Installation & Maintenance Tips

This installation information is a general guide only and may not address your specific site conditions. Always follow local building codes, safety practices, and professional methods. If you are not experienced with this type of work, hire a qualified contractor.

Installation

- Select magnetic driver: Use magnetic nut-setter or hex driver; 410 stainless steel maintains magnetic properties for secure bit engagement.

- Position at connection point: Place Screw at Elbow, Downspout, or component connection requiring premium corrosion protection.

- Pierce without pre-drilling: Self-piercing design penetrates materials efficiently while maintaining holding power in stainless steel construction.

- Drive to proper torque: Tall hex head allows rapid driving; oversized washer provides superior clamping force and pull-out resistance.

Maintenance

- Inspect connections: Check Screw connections during routine maintenance; 410 stainless steel maintains appearance and strength over time.

- Monitor corrosion resistance: Verify stainless steel performance in coastal or high-moisture environments where maximum protection is critical.

- Evaluate long-term performance: Assess connections for any signs of wear; premium stainless construction provides extended service life.

Compare Styles & Materials

410 Stainless Steel vs Rezist® Coated Hex Screws

- 410 Stainless Steel: Maximum corrosion resistance, virtually eliminates staining, ideal for coastal/high-moisture environments, premium cost.

- Rezist® Coating: 1,000-hour red-rust protection, cost-effective upgrade from zinc plating, good for standard outdoor applications.

#8 × ½" vs #10 × 1½" Stainless Steel Screws

- #8 × ½" Screws: Premium non-load-bearing connections including Elbows, Downspout attachments, component fastening with shorter length.

- #10 × 1½" Screws: Premium load-bearing applications for hanging Gutters, heavy-duty hangers, structural connections requiring maximum strength.

Best Choice: Use #8 × ½" 410 Stainless Steel Screws for non-load-bearing connections requiring maximum corrosion resistance, especially in coastal environments or high-moisture applications.

Frequently Asked Questions

This is a general guide only and may not address your specific site conditions. If you are not experienced with this type of work, hire a qualified contractor.

How much longer do Rezist® Screws last compared to standard Screws?

410 stainless steel provides the highest level of corrosion resistance, virtually eliminating rust staining that can occur even with premium coatings. The carbon content forms a protective oxidation film that stops deterioration, making it ideal for demanding environments or premium installations.

Will 410 stainless steel Screws work with magnetic nut-setters?

Yes, 410 stainless steel contains carbon which makes it magnetic, unlike 300-series stainless steels. This allows efficient installation with magnetic nut-setters while providing superior corrosion resistance compared to standard steel fasteners.

What makes 410 stainless steel better than other stainless alloys?

410 stainless steel balances anti-corrosion properties with mechanical strength through its carbon content and heat-treatment capability. This provides better penetration and holding power than softer stainless alloys while maintaining excellent corrosion resistance.

Are these Screws suitable for coastal or marine environments?

Absolutely. 410 stainless steel Screws are specifically recommended for coastal and high-moisture environments where salt air and humidity create challenging conditions for standard fasteners. They virtually eliminate staining and corrosion issues.

How does the cost compare to standard zinc-plated Screws?

While 410 stainless steel Screws cost more than zinc-plated options, the added cost represents only a small percentage of total installation cost while providing significantly longer service life and eliminating potential callbacks from corrosion issues.

Submit an RFQ or Questions

Please feel free to contact us - we promise to respond to your inquiry within the next business day. For longer requests, visit our RFQ page.